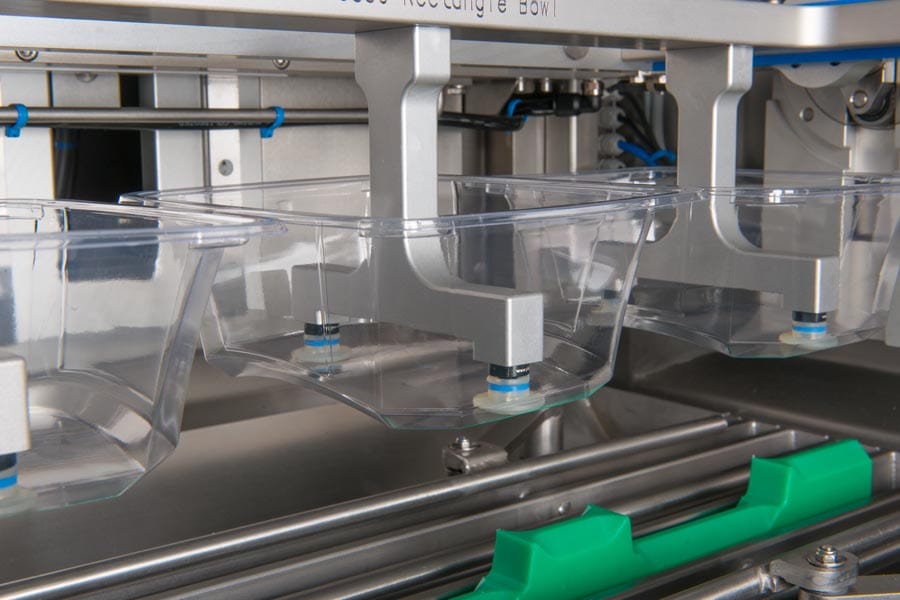

For more than 29 years Tramper Technology has been developing and manufacturing machines and complete production lines for the food processing and packaging industry. With excellent design, state of the art technology and attention to detail Tramper Technology produces machinery for operations as denesting, separating, weighing, filling, distributing, top sealing, lidding & inspecting!

A team of about 50 employees, is working on the creation of innovative solutions. The solutions are completely designed to suit market and customers’ requirements. Most of the the machine- and spare parts are produced in-house by Tramper Technology themselves. For these parts, Tramper Technology uses their own high end quality CNC milling and machining centre.

Throughout many years Finis BV as well as Eillert B.V. have developed into renowned manufacturers of machines and complete production lines for the food Processing industry. Finis is a specialist in equipment for the peeling and processing of various root products and bulbous products like Onions, Potatoes & carrots. Eilert BV has been very successful in serving the leafy vegetable processing industry with equipment for cutting, dicing, washing and drying of a large variety of products.

The complementary activities of both companies result in a complete line delivery program for the fresh market, leading to clear advantages for our clients. The backup of a skilled team of specialists, the international experience and the know-how of both companies offer great added value to the market.

Finis- Eillert Food Processing Equipment

Finis is specialized in the field of Peeling & slicing Technologies for Onions, Potatoes and other bulbous Products. Eillert is specialized in the processing of mostly leafy vegetables.

Innovative thinking has been the ‘spirit’ since INNO-TECH was established. The REVO generation of VFFS machines represents a convincing solution when it comes to, efficient, flexible and modular packaging technology.

The objective when developing the VFFS- Machines was maximum flexibility according to the variety of possible bag types. The constant changing requirements of the market require a concept of VFFS machines which allows the production to produce a big variety of bag shapes and sizes with very little setup times.

Intermittent- or continuous motion, servo-driven film transport belts and sealing jaws and vacuum supported film transport are a few of the possible features. Innovative welding and sealing tools – also with ultrasonic, on request – enable the processing of bulk material, liquid or solid products in various film types.

The synergy between the ELISAM machinery and the vision electronics of the Dutch Mother Company ELLIPS has created the optimum solution for all onions producers, but also for delicate fruits like apples, apricots, kiwi fruit, peaches, tomatoes citrus and many more products. Selection on color, size, weight, external & internal defects, the state of the art equipment from ELISAM makes it all possible

Also, bintippers, binfillers, drying tunnels, palletizers and packing tables are part of the program of Elisam. So whether your products are onions, stone fruit, apples, citrus, dades or tomatoes, Elisam has a solution for our grading queries.

This well-established German company is well known for their high-quality weighing- and counting solutions. In Wetzlar Germany, a highly-motivated team of engineers are producing the Multihead Weighers which are designed to handle a very large variety of products ranging in size from granulates to large and bulky products. Dry or wet, fresh or deep frozen, sea food, meat or petfood, MultiWeigh has the perfect solution for you.

The weighing machines can easily be linked up with all kind of different packaging machines, such as for example the Tramper Tray Seal equipment or the InnoTech VFFS machines. Off course we can also link them up to your existing packaging equipment.

The modular way of building together with their unique and patented “Direct Drive” and “Air Flow” System, distinguishes them from their competition and makes the equipment of very low maintenance. “MultiWeigh, Quality made in Germany”.

The German company Leonhardt has been serving their many customers for many years with high end volumetric dosing equipment for both “pumpable” and “non-pumpable” products. LEONHARDT Piston Fillers and Depositors can be perfectly integrated with new or existing packaging lines,

The unique feature of the LEONHARDT dosing machines is the gentle handling of your products. Moreover, the highest hygiene standard of all their series is well recognised. LEONHARDT’s designs ensure easy disassembly and cleaning of the machine. The highest demands of operating in wet conditions with varying temperatures and strong cleaning detergents are a common place for these machines.

Schut Systems is a 50-year-old Dutch company that has developed into a Key-supplier of Top-Load, End-Load and Sleeving machines.

Top loading packaging lines consist of a carton or tray erector, a filling section and a carton sealer. The blanks are erected to form a box with attached lid. This results in a large fill opening that makes it easy to fill the carton, manually or automatically. Then the filled carton is conveyed to the carton sealer where it is sealed / closed with hot melt.

End loading carton fillers slide the product into the box horizontally. Schut System’s simple, compact, end loading carton fillers are available with manual or automatic infeed.

Due to the extensive knowledge of carton constructions and packaging materials, Schut Systems can critically look at the complete Packaging Process. That is why Schut Systems supplies “Machines with a focus on the packaging”.

Kittner Anlagen-und Maschinenbau is a German company with a long standing and rich history. The Head quarters of the company is based in Kaloyanovo Bulgaria, where also the spacious manufacturing plant is located. For the last 18 years Kittner has been delivering only first class high technology for the food-, chemical- and pharmaceutical industry all over the world. Their Lifting- and Tilting machine for crates, containers & buggies as well as their swing loading equipment is all entirely made out of stainless steel (No. 1.4301). They are easy to clean & maintain, can be used for easy unloading of all different kind of products and is very simple to operate. All products are designed and built to meet the high standards of hygiene, food and personnel safety and will suit different requirements.

Due to the European back ground and European partners, Food Automation has access to a lot of innovative automation solutions. From robotic pick and place solutions up to product specific designed lineair weighing equipment, Food Automation can support your company with this high end equipment.

- Tramper Technology

-

For more than 29 years Tramper Technology has been developing and manufacturing machines and complete production lines for the food processing and packaging industry. With excellent design, state of the art technology and attention to detail Tramper Technology produces machinery for operations as denesting, separating, weighing, filling, distributing, top sealing, lidding & inspecting!

A team of about 50 employees, is working on the creation of innovative solutions. The solutions are completely designed to suit market and customers’ requirements. Most of the the machine- and spare parts are produced in-house by Tramper Technology themselves. For these parts, Tramper Technology uses their own high end quality CNC milling and machining centre.

- Finis - Eillert

-

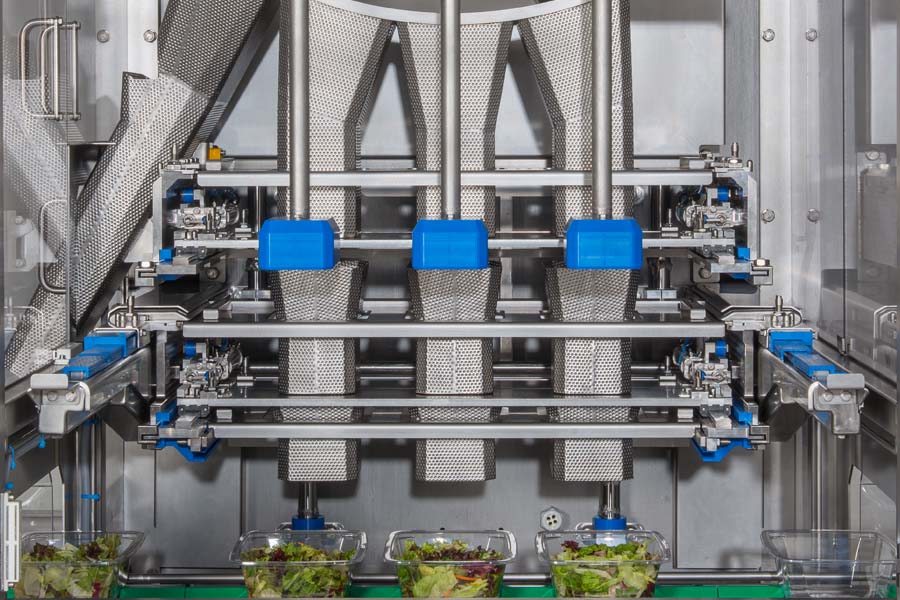

Throughout many years Finis BV as well as Eillert B.V. have developed into renowned manufacturers of machines and complete production lines for the food Processing industry. Finis is a specialist in equipment for the peeling and processing of various root products and bulbous products like Onions, Potatoes & carrots. Eilert BV has been very successful in serving the leafy vegetable processing industry with equipment for cutting, dicing, washing and drying of a large variety of products.

The complementary activities of both companies result in a complete line delivery program for the fresh market, leading to clear advantages for our clients. The backup of a skilled team of specialists, the international experience and the know-how of both companies offer great added value to the market.

Finis- Eillert Food Processing Equipment

Finis is specialized in the field of Peeling & slicing Technologies for Onions, Potatoes and other bulbous Products. Eillert is specialized in the processing of mostly leafy vegetables.

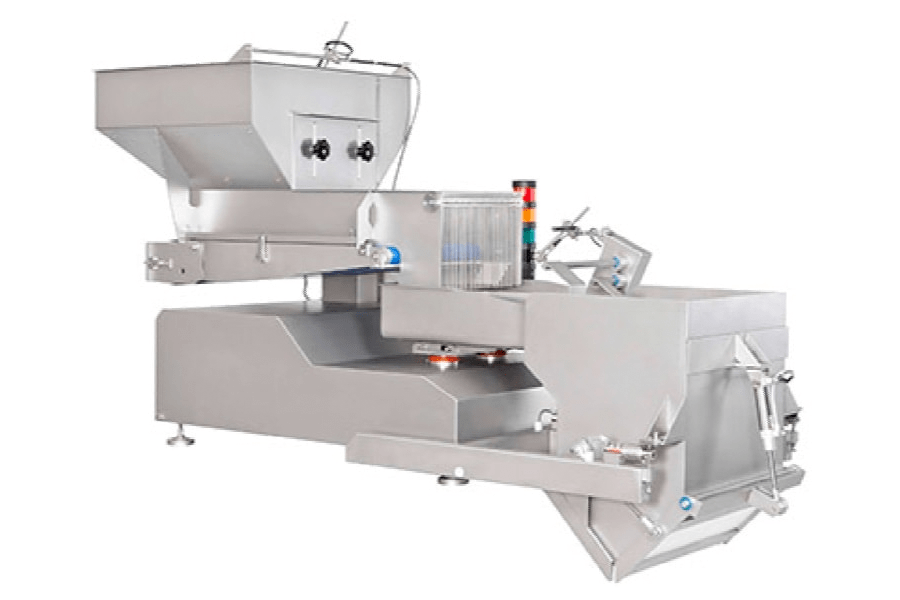

- Inno Tech

-

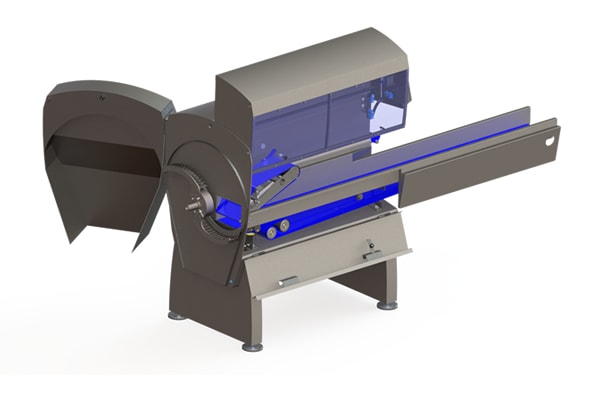

Innovative thinking has been the ‘spirit’ since INNO-TECH was established. The REVO generation of VFFS machines represents a convincing solution when it comes to, efficient, flexible and modular packaging technology.

The objective when developing the VFFS- Machines was maximum flexibility according to the variety of possible bag types. The constant changing requirements of the market require a concept of VFFS machines which allows the production to produce a big variety of bag shapes and sizes with very little setup times.

Intermittent- or continuous motion, servo-driven film transport belts and sealing jaws and vacuum supported film transport are a few of the possible features. Innovative welding and sealing tools – also with ultrasonic, on request – enable the processing of bulk material, liquid or solid products in various film types.

- Elisam

-

The synergy between the ELISAM machinery and the vision electronics of the Dutch Mother Company ELLIPS has created the optimum solution for all onions producers, but also for delicate fruits like apples, apricots, kiwi fruit, peaches, tomatoes citrus and many more products. Selection on color, size, weight, external & internal defects, the state of the art equipment from ELISAM makes it all possible

Also, bintippers, binfillers, drying tunnels, palletizers and packing tables are part of the program of Elisam. So whether your products are onions, stone fruit, apples, citrus, dades or tomatoes, Elisam has a solution for our grading queries.

- MultiWeigh

-

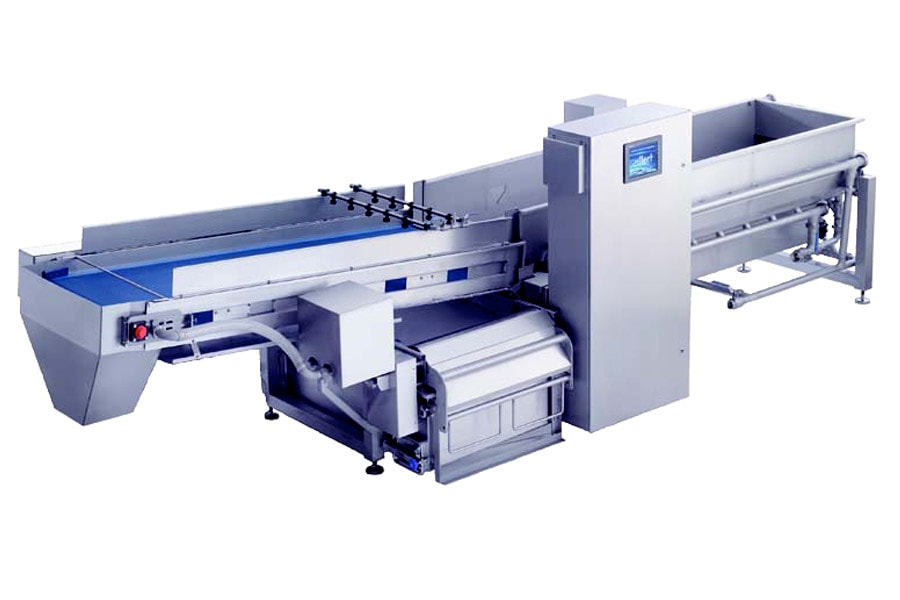

This well-established German company is well known for their high-quality weighing- and counting solutions. In Wetzlar Germany, a highly-motivated team of engineers are producing the Multihead Weighers which are designed to handle a very large variety of products ranging in size from granulates to large and bulky products. Dry or wet, fresh or deep frozen, sea food, meat or petfood, MultiWeigh has the perfect solution for you.

The weighing machines can easily be linked up with all kind of different packaging machines, such as for example the Tramper Tray Seal equipment or the InnoTech VFFS machines. Off course we can also link them up to your existing packaging equipment.

The modular way of building together with their unique and patented “Direct Drive” and “Air Flow” System, distinguishes them from their competition and makes the equipment of very low maintenance. “MultiWeigh, Quality made in Germany”.

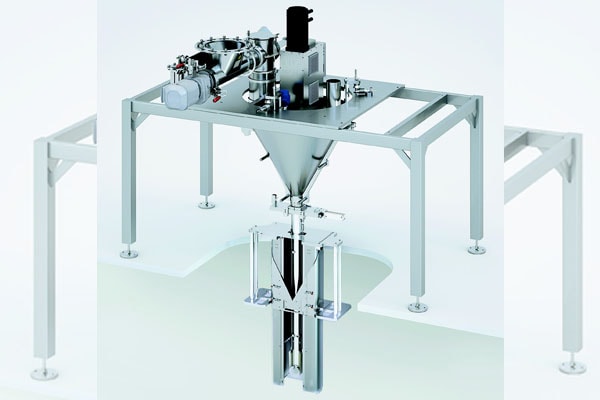

- Leonhardt

-

The German company Leonhardt has been serving their many customers for many years with high end volumetric dosing equipment for both “pumpable” and “non-pumpable” products. LEONHARDT Piston Fillers and Depositors can be perfectly integrated with new or existing packaging lines,

The unique feature of the LEONHARDT dosing machines is the gentle handling of your products. Moreover, the highest hygiene standard of all their series is well recognised. LEONHARDT’s designs ensure easy disassembly and cleaning of the machine. The highest demands of operating in wet conditions with varying temperatures and strong cleaning detergents are a common place for these machines.

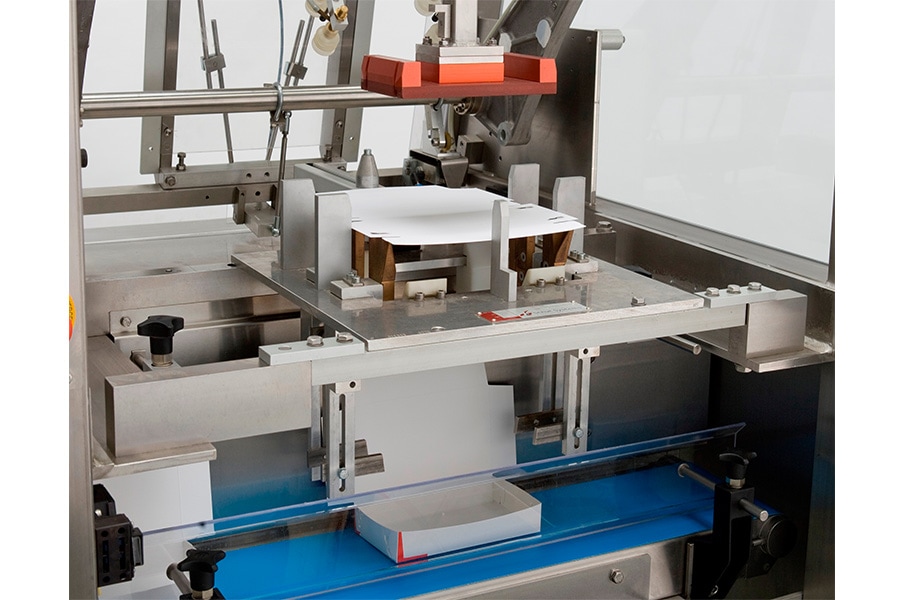

- Schut Systems

-

Schut Systems is a 50-year-old Dutch company that has developed into a Key-supplier of Top-Load, End-Load and Sleeving machines.

Top loading packaging lines consist of a carton or tray erector, a filling section and a carton sealer. The blanks are erected to form a box with attached lid. This results in a large fill opening that makes it easy to fill the carton, manually or automatically. Then the filled carton is conveyed to the carton sealer where it is sealed / closed with hot melt.

End loading carton fillers slide the product into the box horizontally. Schut System’s simple, compact, end loading carton fillers are available with manual or automatic infeed.

Due to the extensive knowledge of carton constructions and packaging materials, Schut Systems can critically look at the complete Packaging Process. That is why Schut Systems supplies “Machines with a focus on the packaging”.

- Kittner

-

Kittner Anlagen-und Maschinenbau is a German company with a long standing and rich history. The Head quarters of the company is based in Kaloyanovo Bulgaria, where also the spacious manufacturing plant is located. For the last 18 years Kittner has been delivering only first class high technology for the food-, chemical- and pharmaceutical industry all over the world. Their Lifting- and Tilting machine for crates, containers & buggies as well as their swing loading equipment is all entirely made out of stainless steel (No. 1.4301). They are easy to clean & maintain, can be used for easy unloading of all different kind of products and is very simple to operate. All products are designed and built to meet the high standards of hygiene, food and personnel safety and will suit different requirements.

- Others

-

Due to the European back ground and European partners, Food Automation has access to a lot of innovative automation solutions. From robotic pick and place solutions up to product specific designed lineair weighing equipment, Food Automation can support your company with this high end equipment.

SEE HOW WE CAN HELP YOU

DECADES OF EXPERIENCE

Entering the packaging industry in 1995 in The Netherlands, Chris de Krom from Food Automation offers over 25 years of experience, of which 15 years is overseas.

LONG TERM THINKING

Because cheap equipment normally turns out to be very expensive, we refuse to make any compromises on quality. High-quality equipment always pays out on the long run

TURN KEY SOLUTIONS

One contact person for the whole job is much easier than one for each piece of equipment. Food Automation and its partners can supply you with stand-alone equipment, but are also specialised in turnkey solutions

EUROPEAN EQUIPMENT

You can benefit from the extensive know-how of suppliers from the Netherlands, Germany, United Kingdom and Italy

GET YOUR FOOD AUTOMATION SOLUTIONS

Food Automation is a manufacturer’s solutions company supplying various grading, processing, weighing, and packing equipment for a wide range of products. Call us on: +61 427 565 658